Can perovskite batteries become a new favorite in the photovoltaic industry?

On June 16, last year, Science magazine reported that Princeton University in the United States has developed the first commercially feasible 2D perovskite solar cell. The team expects its equipment to operate for about 30 years beyond industry standards. If mass production can be achieved, the stability problem of perovskite batteries is expected to be fundamentally solved. If this technology can truly be implemented, combined with the high efficiency and low cost advantages of perovskite batteries, the market for perovskite components will be unlimited. However, in the field of perovskite photovoltaic cells, known as the "third generation photovoltaic cell technology", who can enter the market in the future depends on which production line can be put into operation on a large scale.

Why is it calcium carbide?

In recent years, China's photovoltaic industry has experienced a period of high light, among which the most eye-catching is crystalline silicon batteries. Nowadays, the situation where crystalline silicon batteries dominate the world is expected to be broken by the "third generation photovoltaic cell technology" perovskite. Why was calcium carbide battery technology the first to break through? Compared to crystalline silicon batteries, perovskite photovoltaic cells have shown significant progress in reducing costs and improving efficiency. In other words, perovskite meets the fundamental development requirements of reducing costs and increasing efficiency in the photovoltaic industry.

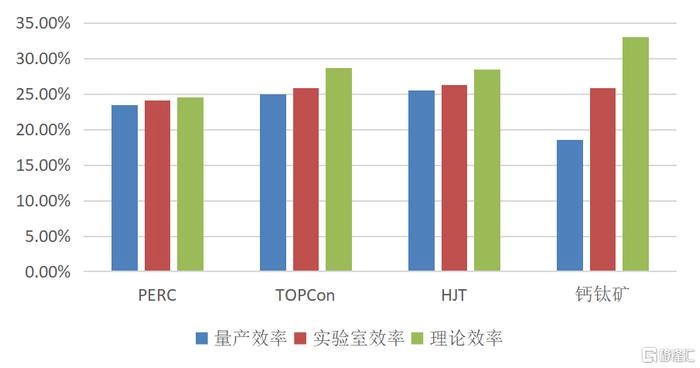

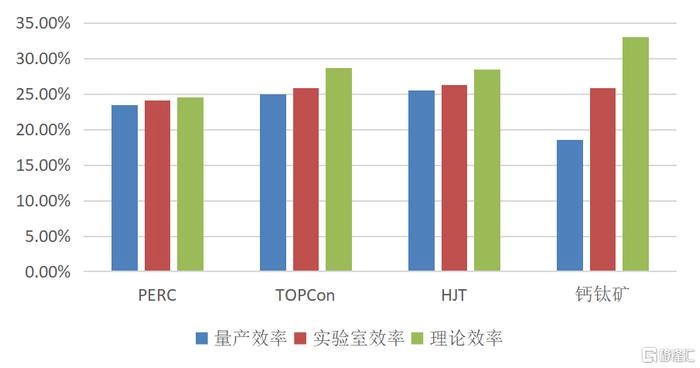

In terms of improving efficiency, perovskite photovoltaic cells have made remarkable progress in the past few years. The maximum efficiency of single junction perovskite type solar cells is currently 25.7%, and stacking with various types of cells can further improve conversion efficiency. The theoretical limit efficiency of double junction stacked cells is 46%, indicating that perovskite materials have great potential for energy conversion performance. In contrast, traditional crystalline silicon solar cells achieved similar efficiency improvements over a longer period of time, approximately 40 years.

The theoretical efficiency of perovskite batteries reaches 33% (source: company announcement, Guotai Junan Securities Research)

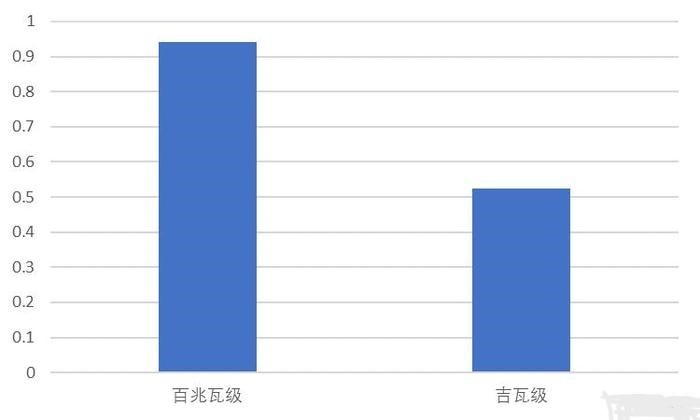

In terms of cost reduction, due to the fact that the perovskite industry chain and process length are shortened by half compared to crystalline silicon, the production cost of perovskite components after large modulus production is expected to be reduced to less than 50% of the ultimate cost of crystalline silicon components. At present, the stacking of perovskite crystalline silicon at both ends combines the advantages of perovskite and crystalline silicon. Among them, perovskite HJT batteries are favored by the industry due to their process adaptability and efficiency potential. Due to the more mature development of crystalline silicon batteries and simpler preparation processes, with the further improvement of stacking efficiency, they are currently the most commercially cost-effective.

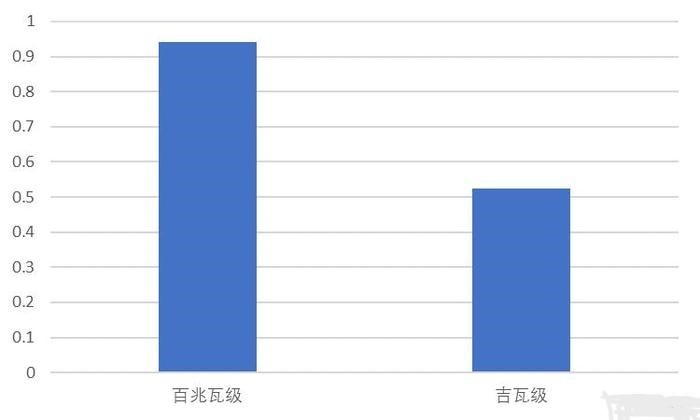

The cost of perovskite batteries is expected to decrease to below 0.6 yuan/W (source: GCL Optoelectronics, company announcement, Guotai Junan Securities Research)

Perovskite photovoltaic, as an emerging photovoltaic technology, not only has laboratory efficiency comparable to that of shoulder crystalline silicon photovoltaic, but also has significant advantages in cost and process. In addition, perovskite photovoltaics have excellent weak light performance and adjustable photoelectric characteristics, which are characteristics that crystalline silicon photovoltaics do not possess. This makes perovskite photovoltaics more imaginative in application scenarios.

The rapidly developing perovskite battery industry:

On November 3rd, Longji Green Energy was certified by the National Renewable Energy Laboratory (NREL) of the United States. The company's independently developed crystalline silicon perovskite stacked battery achieved an efficiency of 33.9%, which is currently the highest record for the efficiency of crystalline silicon perovskite stacked batteries worldwide. Previously, the record was 33.7%.

Photovoltaic leaders lay out crystalline silicon layers and promote industrial development through multiple routes. At present, the layout of listed companies mainly focuses on perovskite crystalline silicon stacking, with perovskite stacking Perc/Topcon/HJT multiple routes coexisting. For example, photovoltaic leaders such as Longji Green Energy and Tongwei Co., Ltd. have successively entered the market, which is expected to promote the industrial development of stacked batteries. The start-up company's stacked batteries cover multiple fields such as full perovskite stacking, perovskite crystalline silicon stacking, perovskite copper indium gallium selenium stacking, etc. The final victory of the specific route also depends on the future efficiency improvement and cost reduction effects.

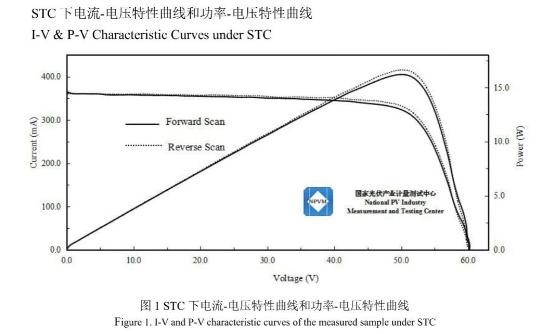

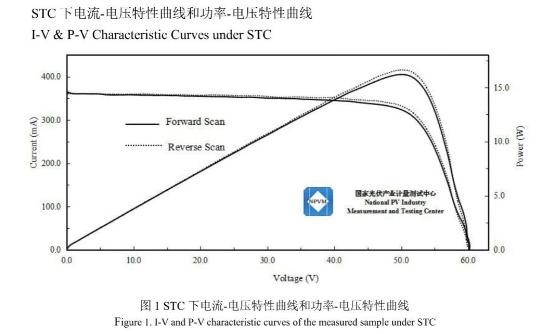

On October 27th, after being certified by the National Photovoltaic Industry Measurement and Testing Center, Photovoltaic Technology achieved an efficiency of 21.63% on 30cm * 40cm large-area perovskite battery modules, continuing to lead the perovskite battery industry. (The test results are from the National Photovoltaic Industry Measurement and Testing Center)

It should be pointed out that laboratory level efficiency still needs to be validated in large-scale production, and stability challenges still exist. However, the rapid development of perovskite photovoltaic cells provides an accurate and powerful solution for reducing costs and increasing efficiency in the photovoltaic industry, and its broad market prospects are beyond doubt.

From the perspective of production line scale and project progress in the perovskite industry, 2022 is the first year of perovskite industrialization. In this year, the perovskite industry was not only able to stably produce qualified products, complete shipments and engineering construction on time, but also smoothly connect terminals to the grid for power generation. With the advancement of industrialization, related enterprise investment and financing events have become active, and dozens of new startups have been established in the perovskite field.

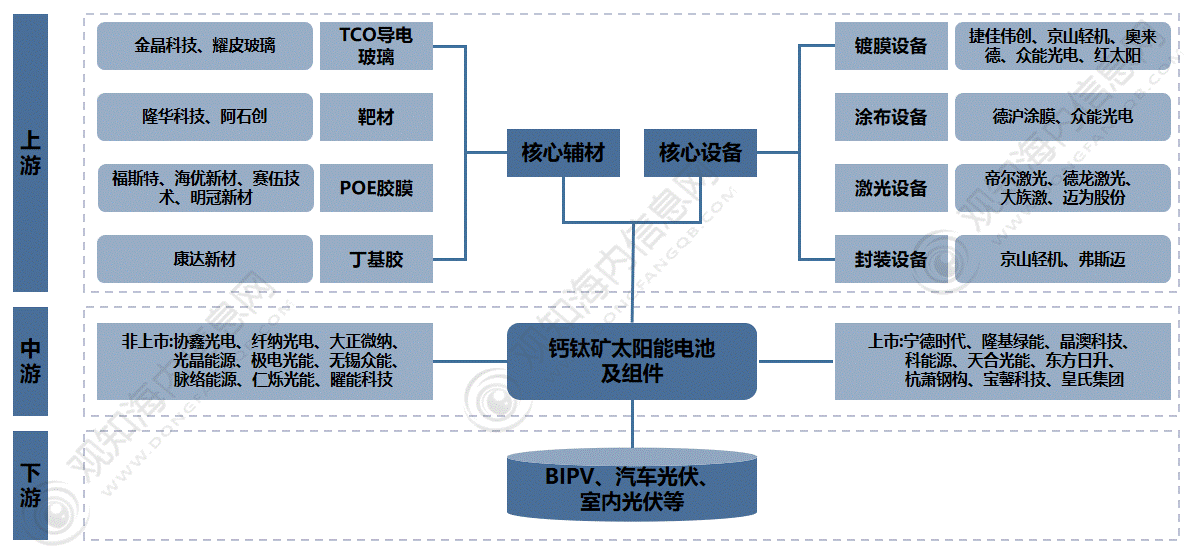

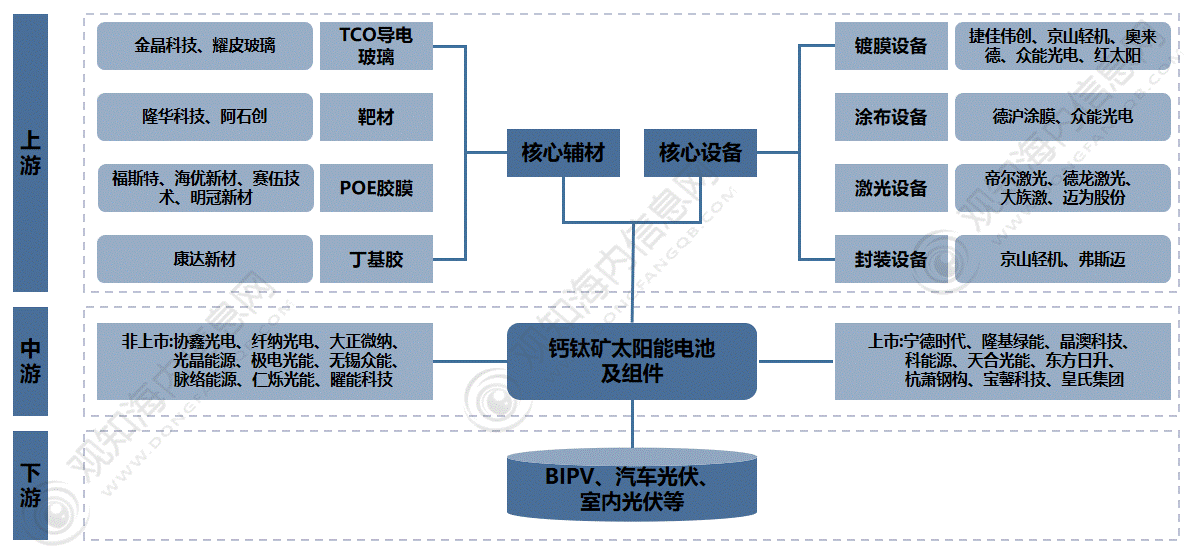

Schematic diagram of China's perovskite battery industry industry chain Source: Guanzhi Hainei Consulting

There has been considerable progress in the commercialization of calcium titanium minerals in the industry. In April this year, the 1GW perovskite photovoltaic production line with a total investment of 3 billion yuan in polar photovoltaics began construction, and is expected to be put into operation in the third quarter of next year; The Renshuo Solar 150MW production line will be put into operation by the end of this year, and the component area will be enlarged to 1.2m * 0.6m. Guangyin Technology completed a 50 million angel round financing in early April 2023, setting a record for the largest single angel round financing in the industry. Its 10MW small trial line began construction in mid April 2023 and was completed by the end of June, making it the world's fastest to put into operation. It is expected that a 100MW pilot line will be completed by the end of 2024, and the component area will be expanded to square meters.

It can be foreseen that the expansion of industrial production will accelerate in 2024, with more 100 MW level production lines and some GW level production lines starting and operating. 2025 may enter the mature commercialization stage ahead of schedule

Figure: Opening Ceremony of the 1GW Perovskite Photovoltaic Production Line with Polar Solar Energy

The future track has emerged, where are the pain points

In the field of perovskite photovoltaic cells, there is a state of contention among a hundred schools of thought. Whether it is perovskite crystalline silicon stacking, perovskite layered Perc/Topcon/HJT technology, or all perovskite stacking, perovskite copper indium gallium selenium stacking, and other technologies, the future perovskite battery technology environment is likely to have the phenomenon of multiple technologies coexisting with the current crystalline silicon battery, The final market share and survival of the fittest still depend on the demand for future application scenarios.

Although the cost reduction and efficiency enhancement of perovskite photovoltaic cells have long been proven feasible at the technical level, the ultimate pain point cannot be separated from the demand for cost reduction and efficiency improvement in the photovoltaic industry. This means that perovskite batteries need to solve not only the stability of the product itself, fast efficiency decay rate, and toxic lead content during the production stage. The more fundamental issue is that if we want to gradually replace the current market situation dominated by crystalline silicon batteries, we must quickly promote the efficient and low-cost perovskite photovoltaic battery industry chain and mass production capacity.

With the continuous progress of perovskite battery technology, the growth of market demand, capital investment, and continuous policy support, we have every reason to believe that perovskite batteries are expected to gradually achieve commercial large-scale applications and become an important pillar of the photovoltaic industry.

At RONGSTAR Energy we are proud to play a part in the global solar energy development. We have years-long experience in the distribution and wholesale supply of photovoltaic solar panels, inverters, construction, storage systems and other components for photovoltaics. View more photovoltaic products and solutions- Deye Inverters,TW SOLAR Panel,APsystems Solar Inverter Distributor (rongstar.com).

IPv6 network supported

IPv6 network supported